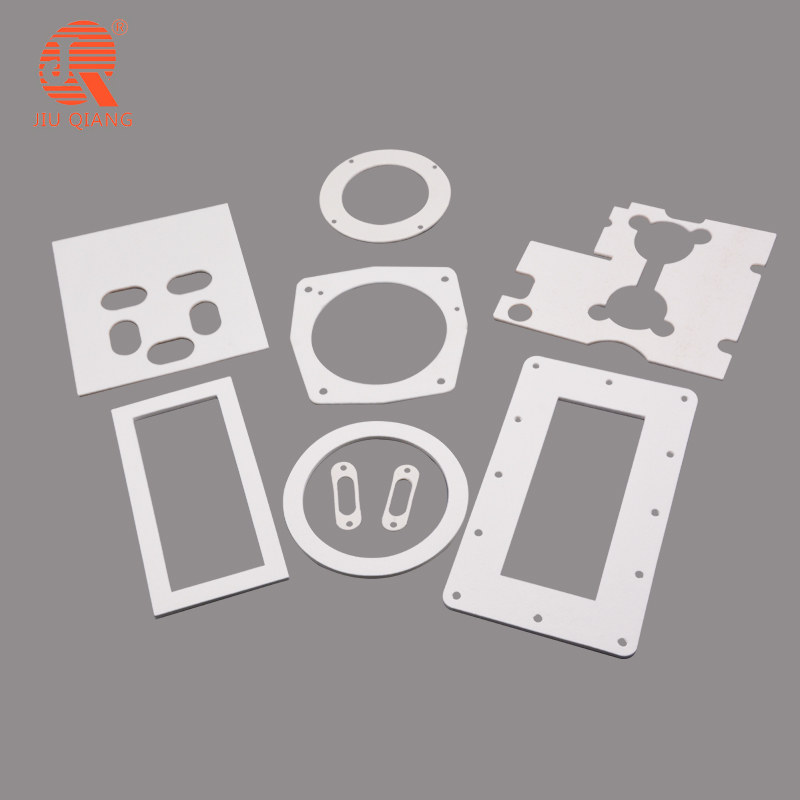

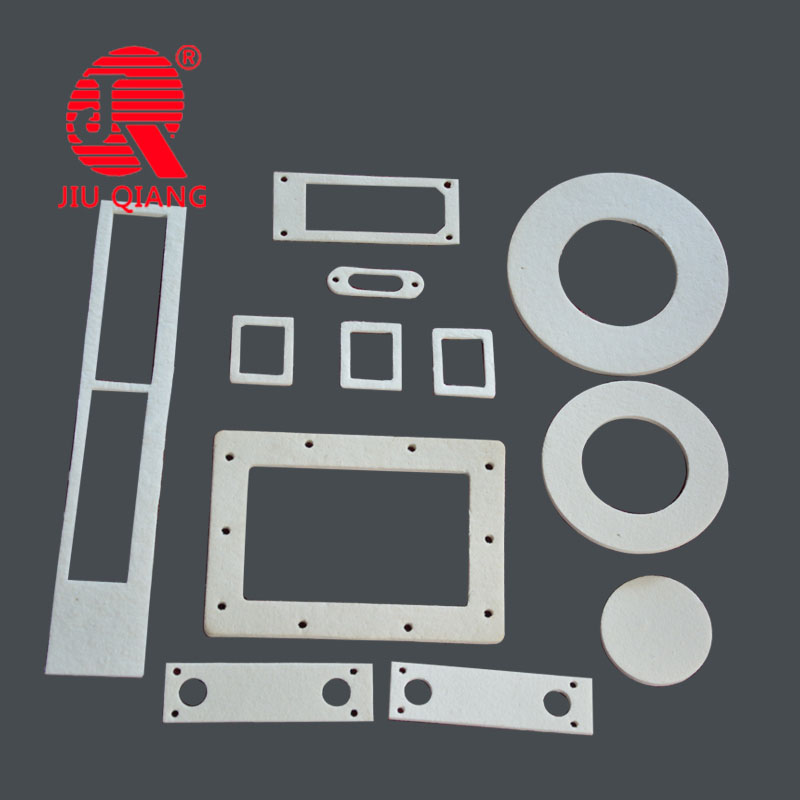

High Temperature Thermal Insulation Ceramic Fiber Gasket

Various shapes can be processed according to customer needs.

● Tap Hole cones.

● Riser Sleeves.

● Riser Sleeves.

● Ladle lining.

● Pouring Cups.

advantage

The advantage of ceramic fiber shape

1. Low thermal conductivity and low heat storage.

2. High compress strength.

3. Easy to install.

4. Excellent heat stability and thermal shock resistance.

5. Smooth surface.

Low impurity, and average bulk density and thickness.

Excellent mechanical strength and structural strength.

application

The application of ceramic fiber shape

1. Industrial furnace wall lining and bricking-up insulating layer.

2. Heat insulation material for the high temperature and high-heat equipment.

3. Heat insulation, fireproof, sound insulation and electric insulation material for the aerospace and shipbuilding industry.

4. High temperature kiln lining, kiln car, door baffles and the kiln dividers.

Data sheet

| Grade | Standard | High Aluminum | Zirconium | ||

| Classification Temperature(℃) | 1260℃ | 1300 | 1430 | ||

| Working Temperature (℃) | 1150℃ | 1260 | 1400 | ||

| Density (kg/m3) | 300-450KG/M3 | ||||

| Thermal conductivity by mean temp.(w/m.k.) (Density 285kg/m3) | 0.085 (400℃) 0.132 (800℃) 0.180 (1000℃) |

||||

| Compression Strength (Mpa) | 0.5 | ||||

| Toughness | Good tough | ||||

| Wear Resistance | Some | ||||

| Chemical Composition | AL2O3 | 42-43 | 52-55 | 32-33 | |

| AL2O3+SIO2 | 97 | 99 | -- | ||

| ZrO2 | -- | -- | 15-17 | ||

| Fe2O3 | <1.0 | 0.2 | 0.2 | ||

| Na2O+K2O | ≤0.5 | 0.2 | 0.2 | ||

| Remarks: the data above is for reference. The Max. temp. depends on the working conditions. | |||||

Packages of ceramic fiber shape

1. Carton and plastic bag inside.

2. Pallet, for load and unload consideration.